Visit and Seminar by Professor ANDREAS HORNUNG (Director of Fraunhofer Institute)

Host: Nuno Lapa, LAQV - FCT NOVA

10:00 h - 10:15 h | Welcome message

(FCT Dean - to be confirmed; Vice-director for Scientific Affairs; President of the Department of Chemistry)

10:15 h - 11:00 h | Seminar: STANDARD FUELS FROM SOLID WASTE BIOMASS BY THERMO-CATALYTIC REFORMING

(Professor Andreas Hornung, Diretor do Fraunhofer Institute)

See below Abstract and Short Bio

11:00 h - 11:15 h | Introduction to the Department of Chemistry

(President of the Department) and Possible collaborations between the Fraunhofer Institute and FCT-NOVA-DQ (MAC members)

11:15 h - 12:00 h | Visit to the Department of Chemistry

11:17 h - 11:27 h | Visit to Ana Aguiar-Ricardo's group (5th floor)

11:28 h - 11:38 h | Visit to Isabel Fonseca's group (5th floor)

11:40 h - 11:50 h | Visit to Susana Barreiro's group (4th floor) and Pilot Plant

11:53 h - 12:03 h | Visit to Ascenção Reis's group (1st floor) - Pilot Plant

Abstract - STANDARD FUELS FROM SOLID WASTE BIOMASS BY THERMO-CATALYTIC REFORMING

Key Words: Thermo-catalytic Reforming, Biomass conversion, Standard fuels.

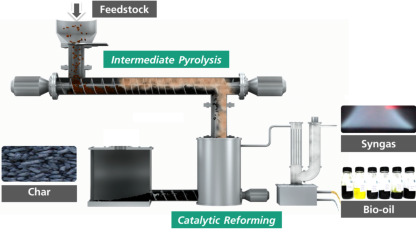

Intermediate pyrolysis describes a process of converting feedstock by heating it up in the absence of oxygen under moderate, “intermediate” conditions. Typical conditions are a residence time for solids between 5 to 30 minutes, low heating rates and temperatures between 350 °C - 450 °C. Due to these conditions intermediate pyrolysis has remarkable advantages regarding the feedstock, compared to other processes based on flash pyrolysis. Large particles, like pellets or chips can be used. Dry matter content can be below 50% from a technical point of view. For economic reasons the dry matter should be more than 70 % to avoid using energy mainly for drying. However, this dry matter is still very low compared to the requirements of most flash pyrolysis reactors. Another advantage is the use of variable and heterogeneous feedstock, preferably residue and waste biomass. The feedstock can vary from agricultural residues, biogas digestate, municipal and industrial biowaste to sewage sludge. The latest development of the intermediate pyrolysis technology is Fraunhofer UMSICHT´s Thermo-Catalytic Reforming process (TCR®). It is a novel process for the production of char, gas, and bio-oils with improved properties.

One significant innovation of TCR® is the integrated downstream catalytic reforming step. This multi-patented technology enables the high quality of the final products carbonisate, syngas, and oil. The robustness of the process permits the utilization of various biogenic feedstocks. The yield of the products depends on the chemical properties of the feedstocks, whereas the quality and characteristics of the products are due the robustness of the process, largely independent of the feedstocks. With the focus on the TCR® oil there is one unique selling point: The oil is thermally stable and therefore distillable. This is the basis for other thermal upgrading processes like e.g. hydro-treatment. Furthermore, the thermal stability of the TCR® oil is a basic prerequisite for usage in the fossil petrol processing industry. This includes, among other applications, combined heat and power (CHP) plants. Additional unique properties are the low water content, the low total acid number, and the high heating value. The high quality of the crude TCR®-oil can be further improved to EN fuel quality by distillation and hydrodeoxygenation (HDO). For hydrodeoxygenation sulfonated NiMo catalyst at temperatures of around 370 °C and a pressures in the range of 140 bar and with LHSV of 0.3 per hour were applied. The resulting products showed full properties of standard hydrocarbon fuels. A separation into diesel and petrol fraction by rectification demonstrated, that both fractions met the fossil fuel standards (EN 228 and EN 590).

Through hydrotreating the hydrogen content was increased and the oxygen, sulphur and nitrogen content was significant lowered or respectively removed in an efficient way with a yield over 85 %.

The fuel has been tested by a Volkswagen XL 1 car under real road condition for several hundred kilometres with an average diesel consumption of 1.3 litres per 100 km. The TCR technology has been tested and applied in laboratory scale (2kg/h throughput), pilot scale (30 kg/h throughput) and industrial scale (300kg/h throughput). In the frame of a Horizon 2020 demonstration project a TCR 500 (500kg/h throughput) integrated with a hydrogenation unit is now being constructed and will be in commissioning beginning of 2020.

Figure 1. Scheme of TCR-reactor

Figure 2: TCR crude and hydrogenated TCR fuel

Short Bio

Prof. Dr. rer. nat. Univ.-Prof. Dipl-Ing.

Andreas Hornung CENG FRSC FICHEME

Prof. Dr. Andreas Hornung studied for his first degree at Technical University Darmstadt in Germany. He completed his doctorate in Natural Sciences at Technische Universitaet Kaiserslautern. Prof. Hornung is an expert in thermo catalytic conversion of biomass and organic residues for sustainable fuels and chemical synthesis. He has over 25 years’ experience in developing novel reactor systems for the conversion of biomass and has expertise in designing, building and operating reactor units to achieve desired outcomes at all scales of operation. Prof Hornung currently holds positions as Director of the Fraunhofer Institute, Sulzbach-Rosenberg, Germany. Furthermore he keeps the Chair in Bioenergy at the University of Birmingham (UK) and is Professor in High Temperature Process technologies at the Friedrich-Alexander University Erlangen-Nürnberg (Germany). He currently holds 21 patents and has published over 250 scientific papers.

Relevant publications / Topic biochar and nutrient recovery

Scenario based nutrient balance of digestate and manure for excess modelling in Bavaria. Progress in Biogas IV University of Hohenheim – Stuttgart 2017; ISBN: 978-3-940706-09-6

Synthesis of green fuels from biogenic waste through thermochemical route – The role of heterogeneous catalyst: DOI:10.1016/j.rser.2014.05.011

Thermo-Catalytic Reforming of municipal solid waste DOI:10.1016/j.wasman.2017.06.044

Steam gasification of rapeseed, wood, sewage sludge and miscanthus biochars for the production of a hydrogen-rich syngas DOI:10.1016/j.biombioe.2014.07.025

Upgraded biofuel from residue biomass by Thermo-Catalytic Reforming and hydrodeoxygenation DOI:10.1016/j.biombioe.2016.03.002

Profiles of volatile organic compounds in biochar: insights into process conditions and quality assessment. ACS Sustainable Chemistry & Engineering 10/2016; DOI:10.1021/acssuschemeng.6b01869

Transformation of Biomass - Theory to Practice. Edited by A. Hornung, 01/2014; Wiley Verlag., ISBN: 978-1-119-97327-0